Tristars Precast Concrete division produces architectural elements for commercial, multi-family and residential projects. Stock items are sold through our distributors, and we offer custom-shaped products to suit your specific requirements.

Precast concrete offers an almost endless variety of products and design options for both aboveground and underground construction. From the largest infrastructure projects to the smallest architectural details, precast is one of the most versatile and sustainable building materials available for todays fast-paced, environmentally conscious construction.

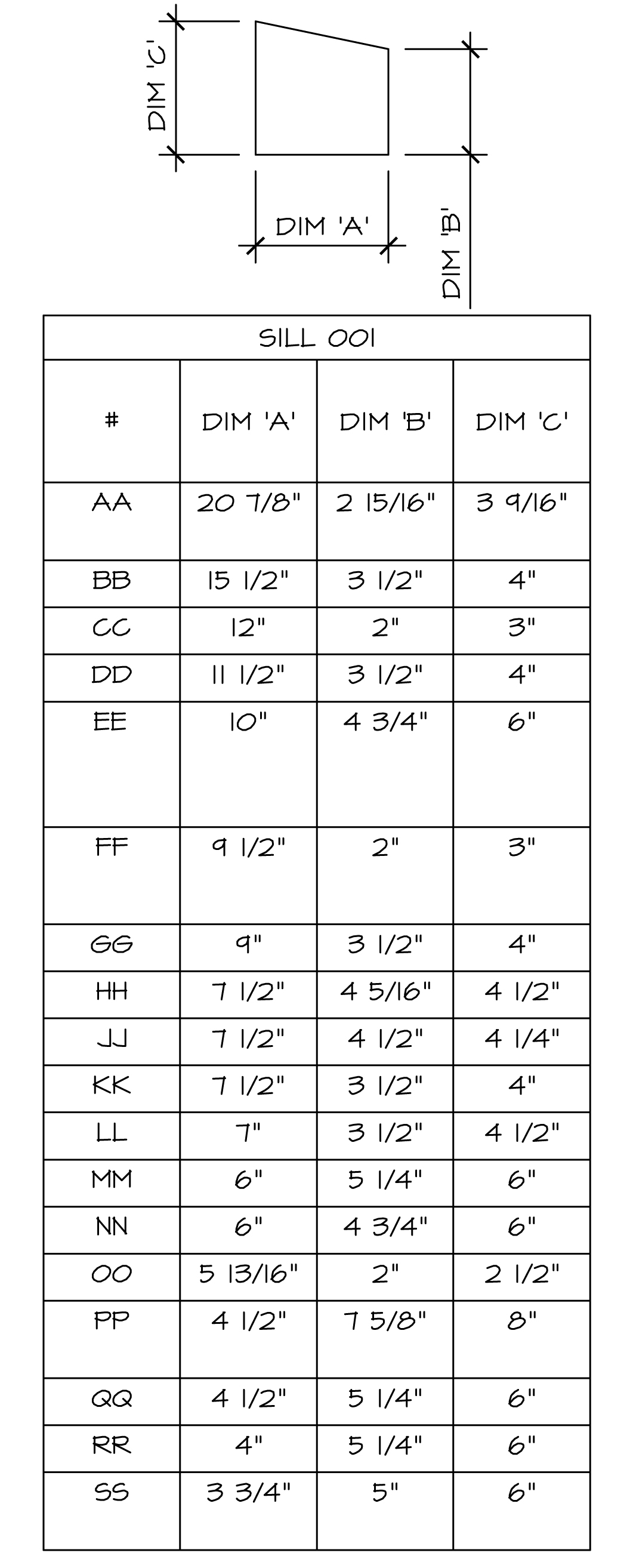

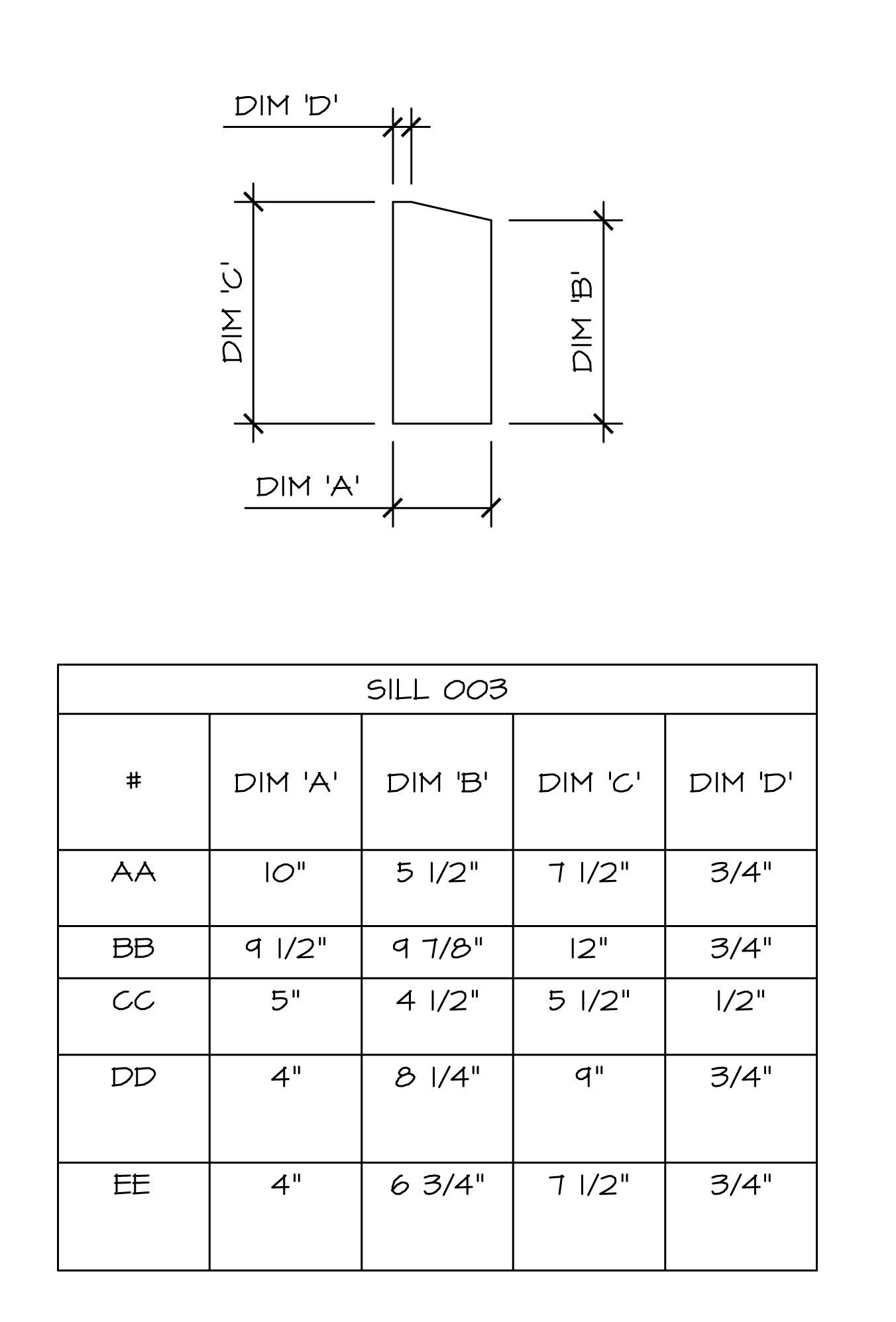

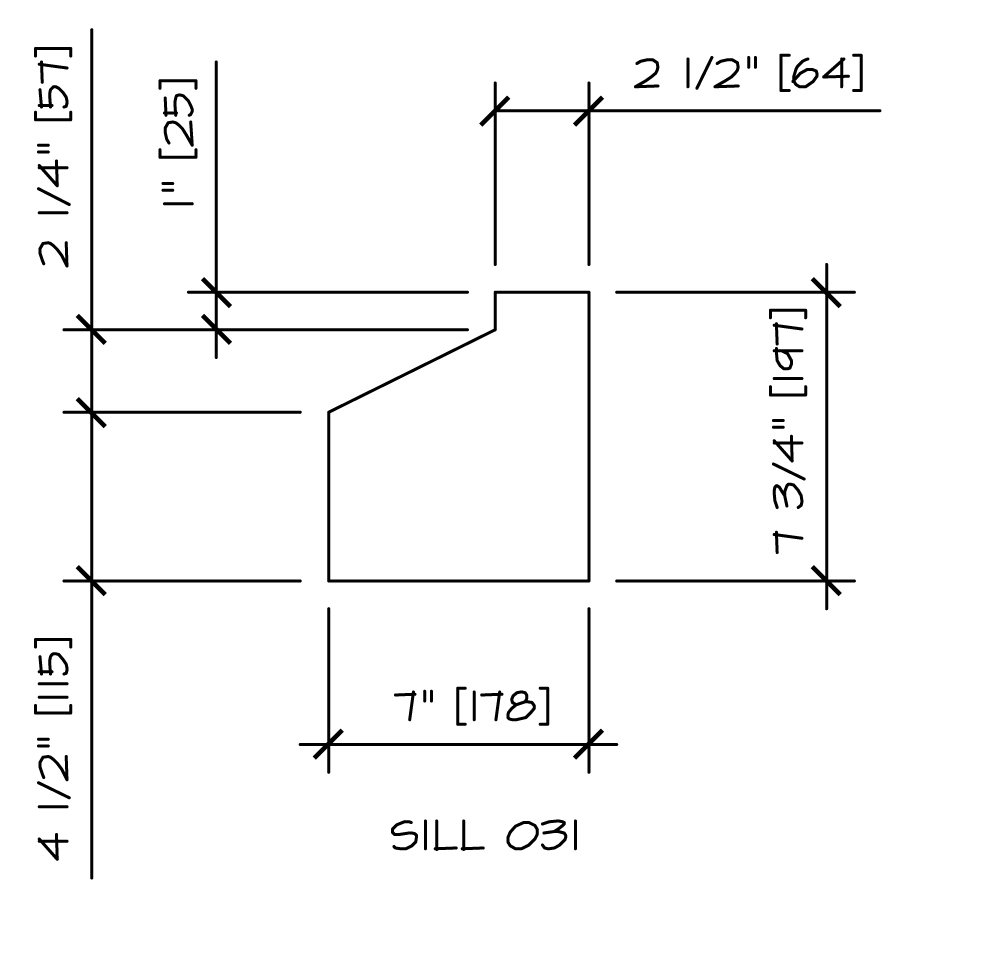

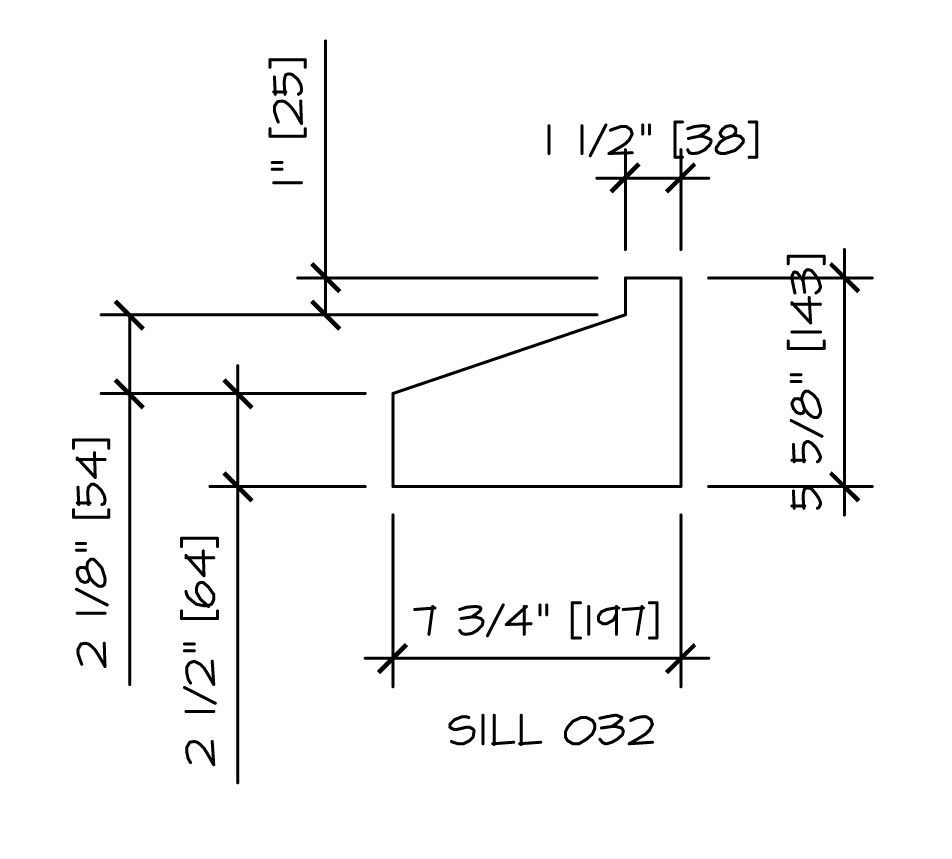

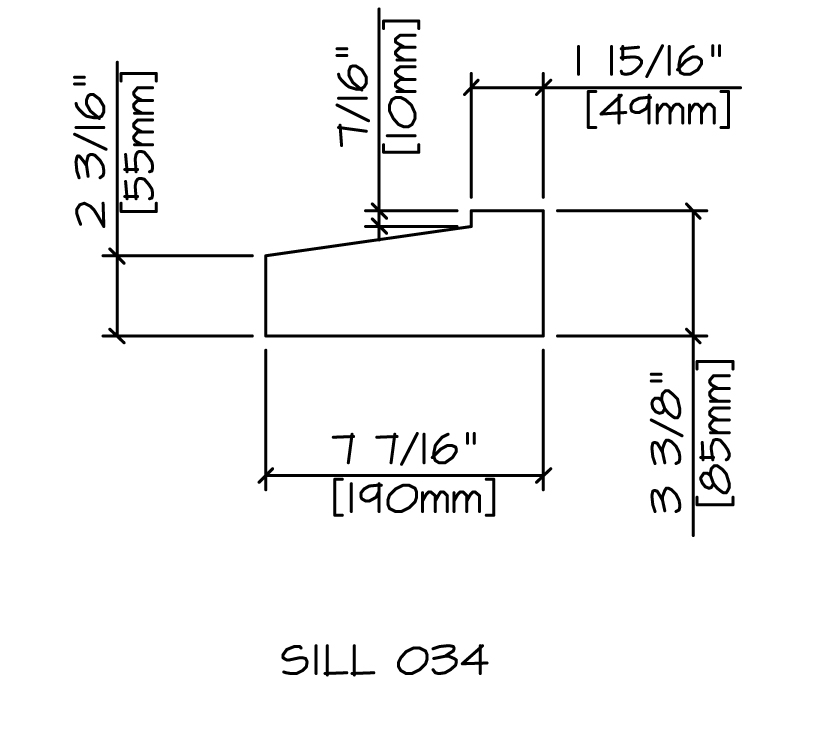

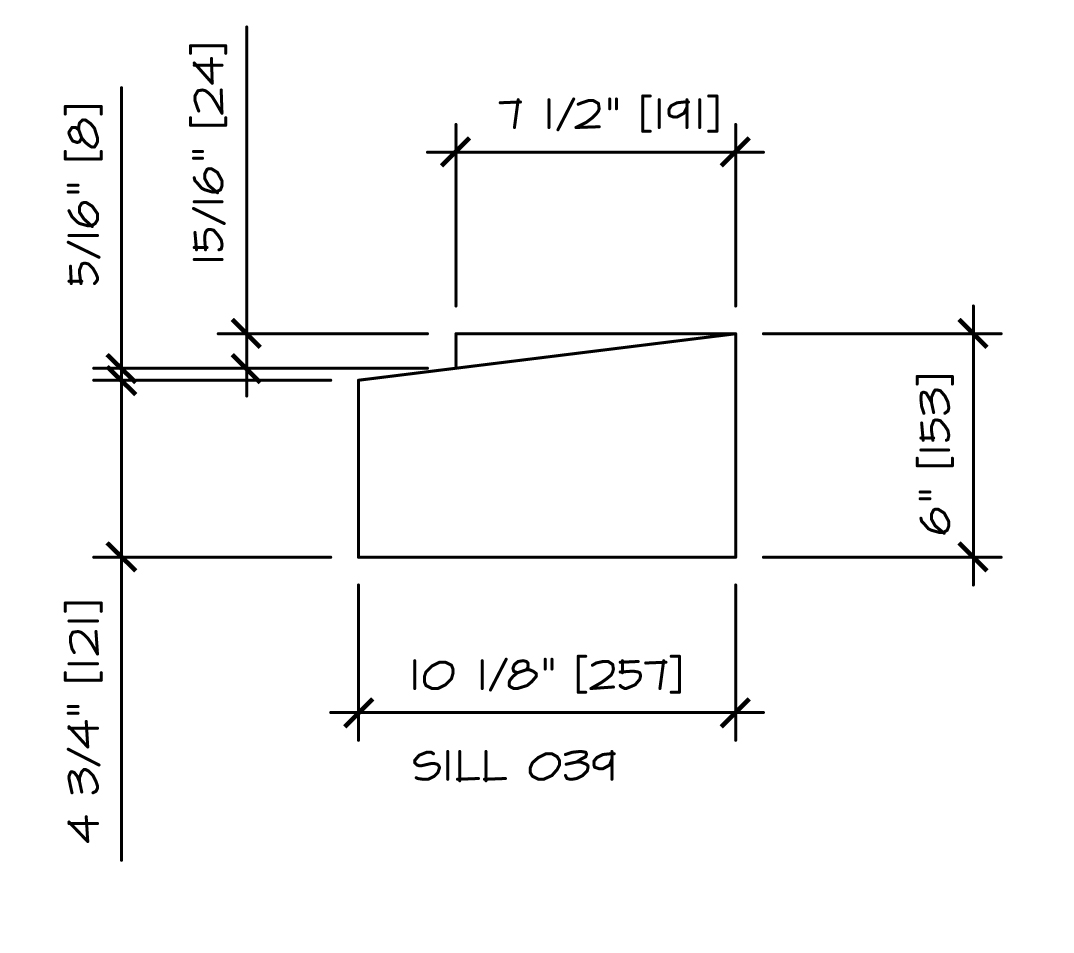

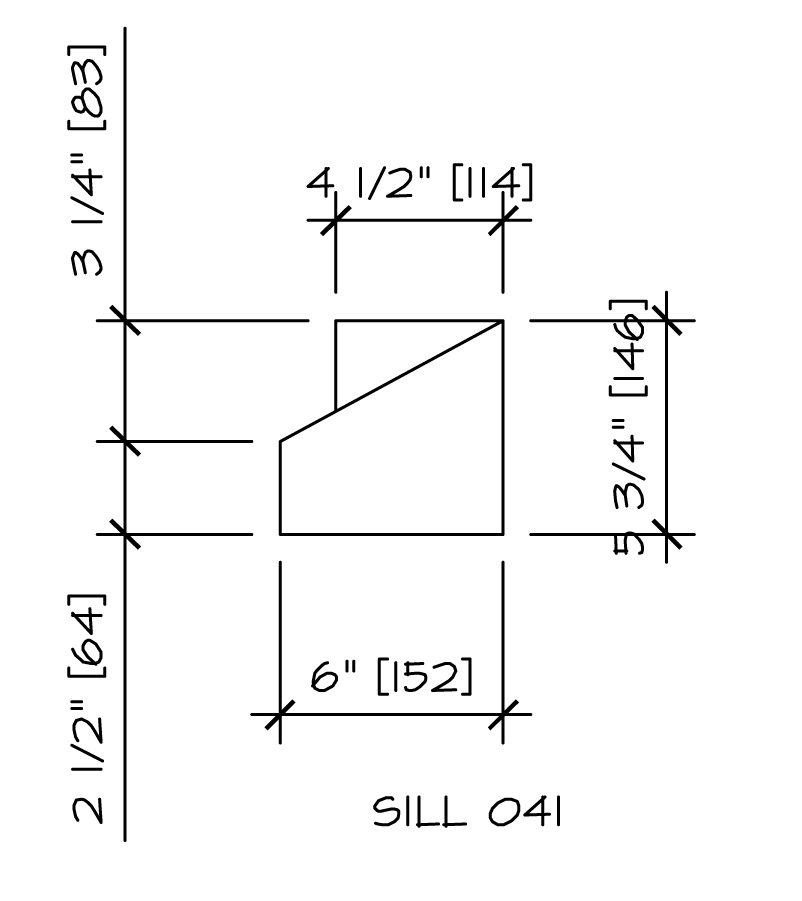

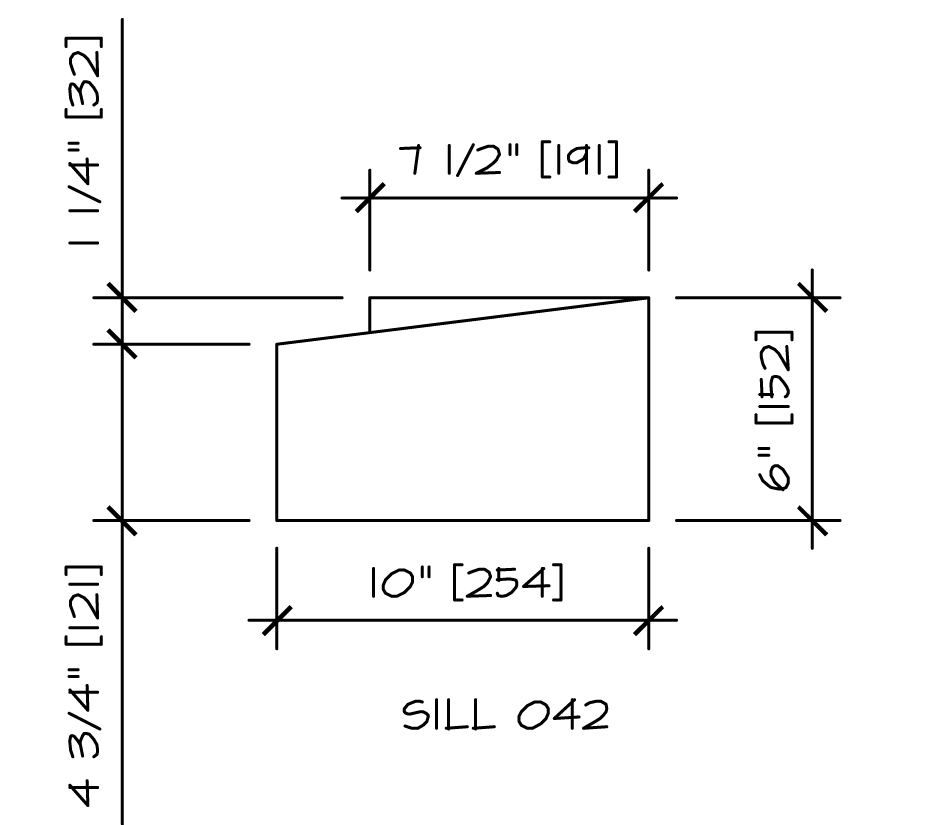

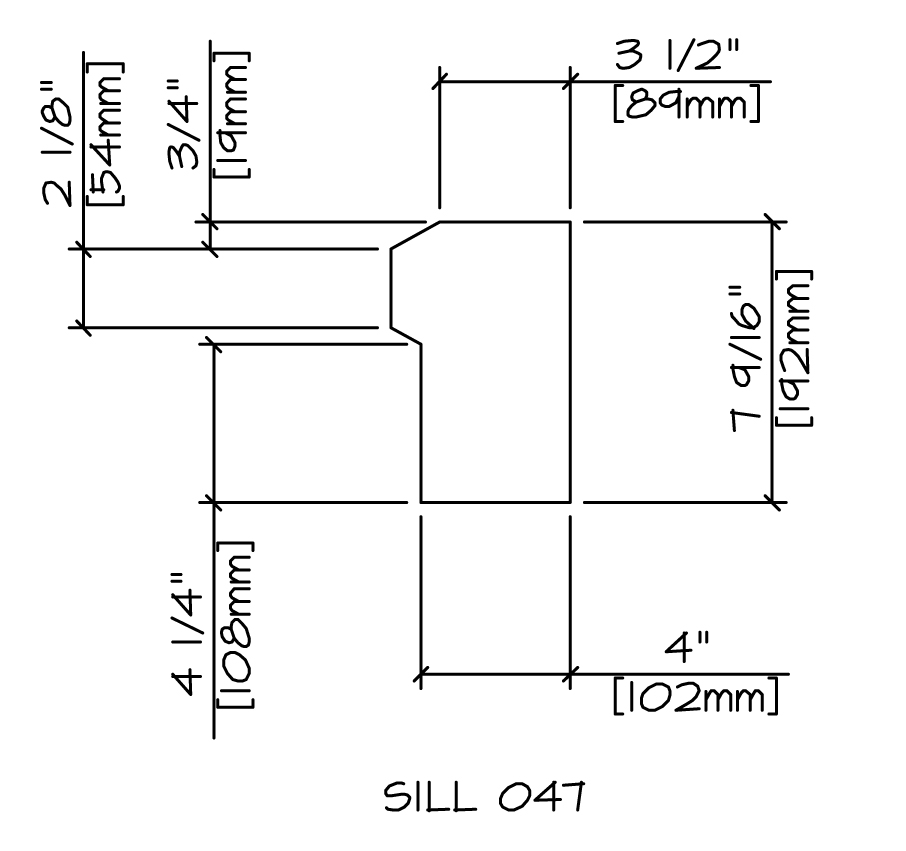

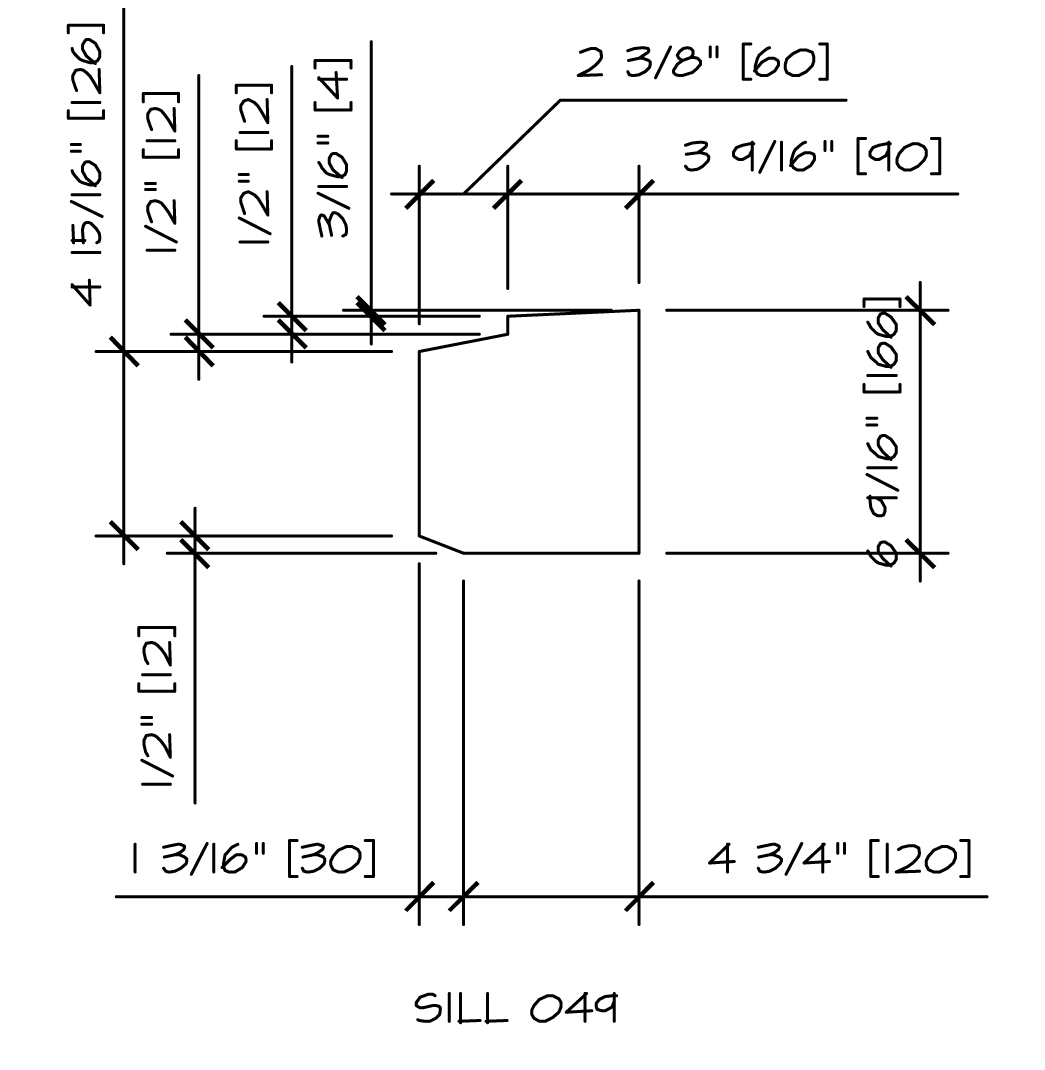

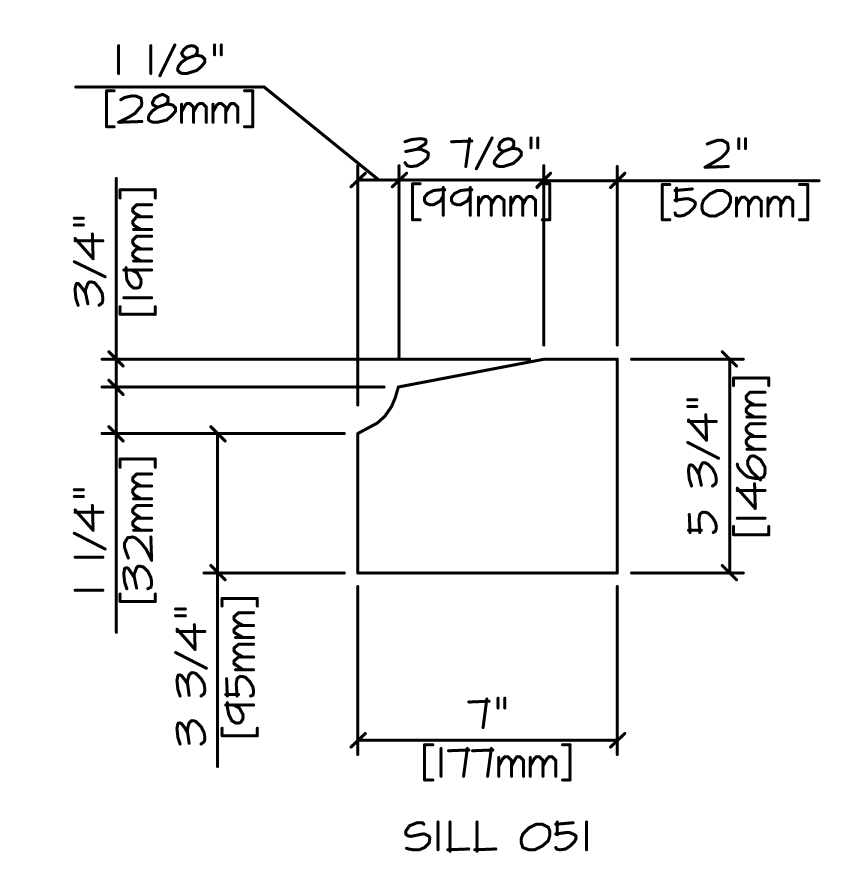

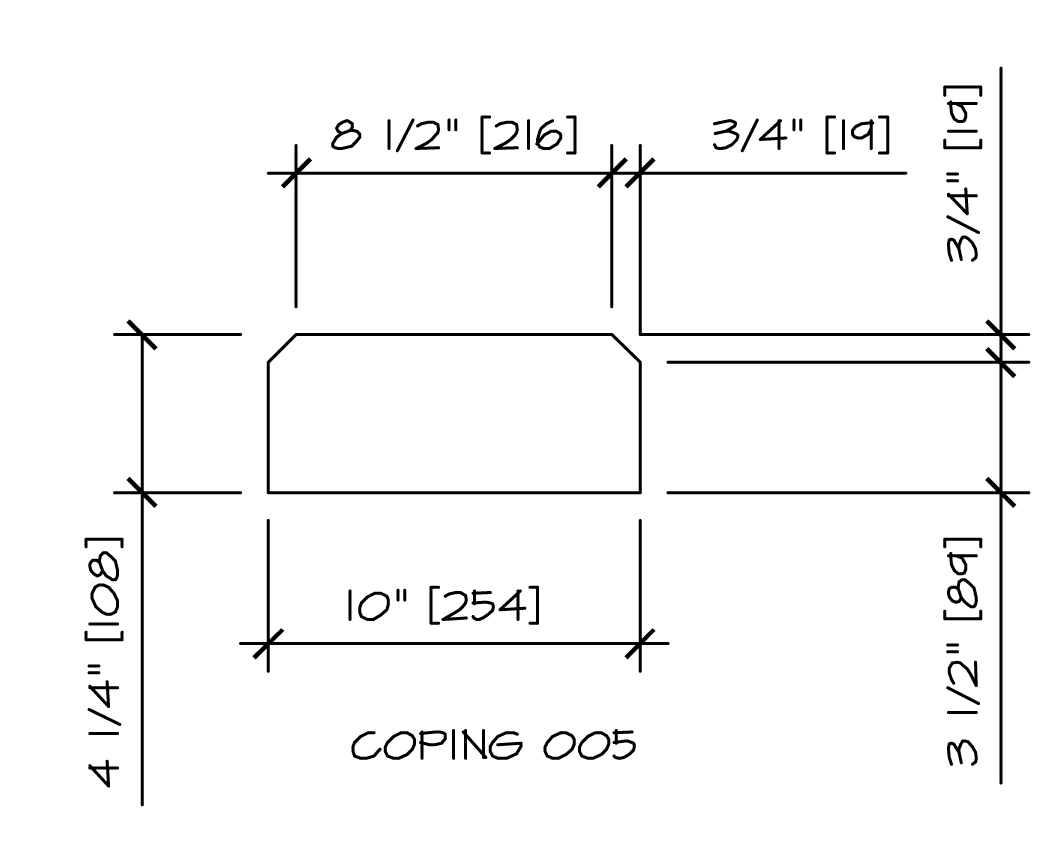

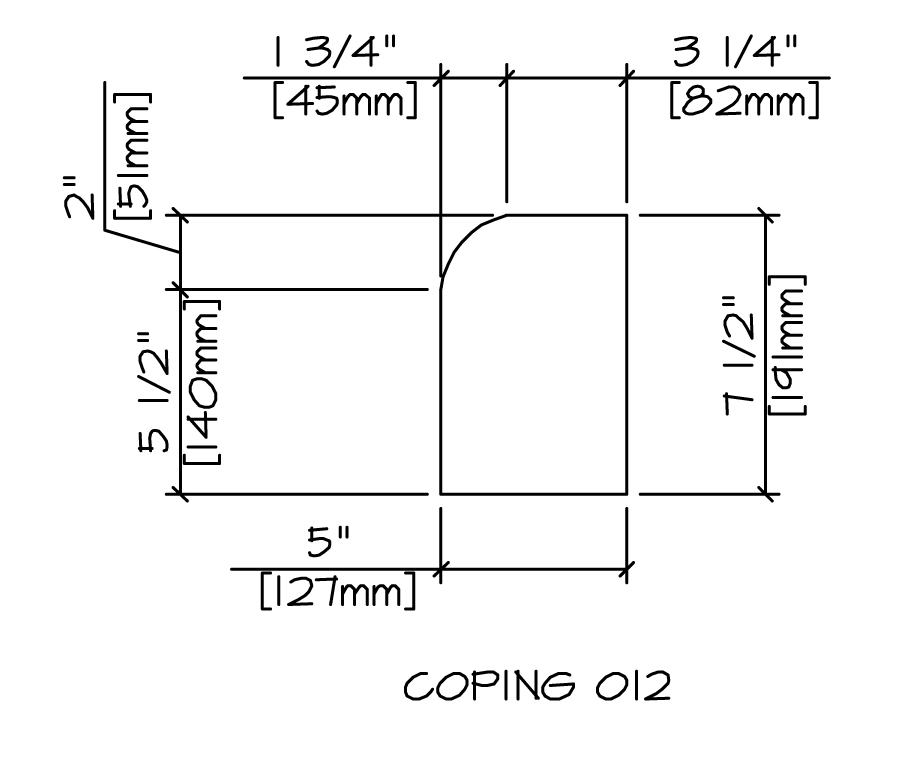

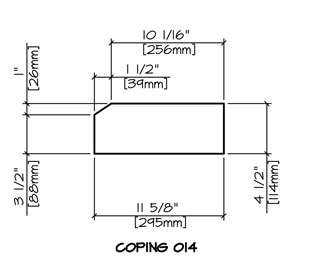

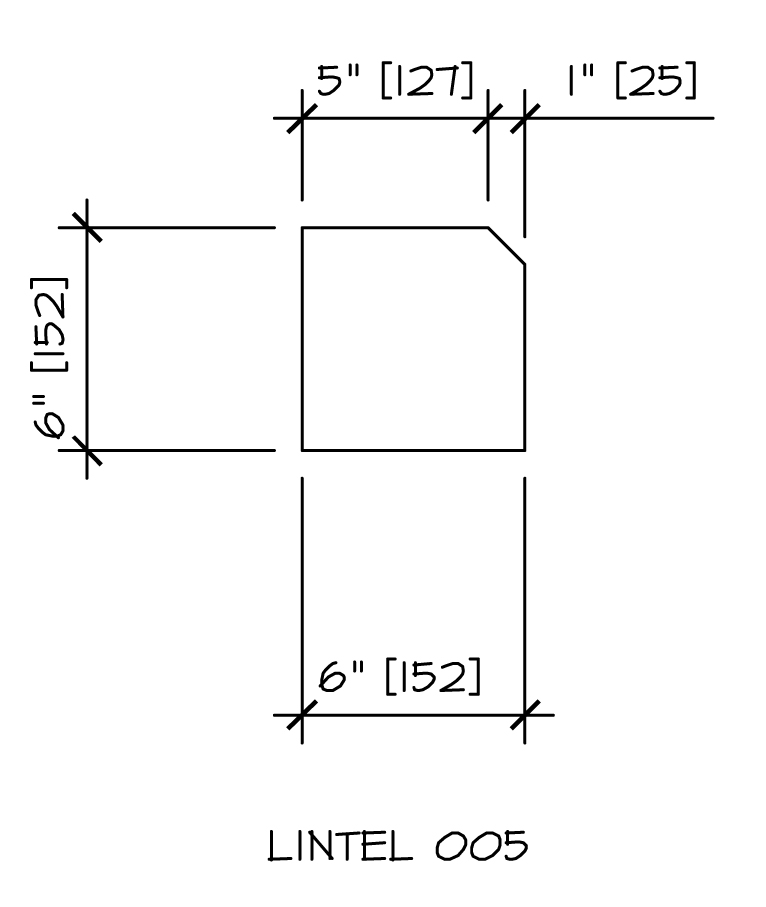

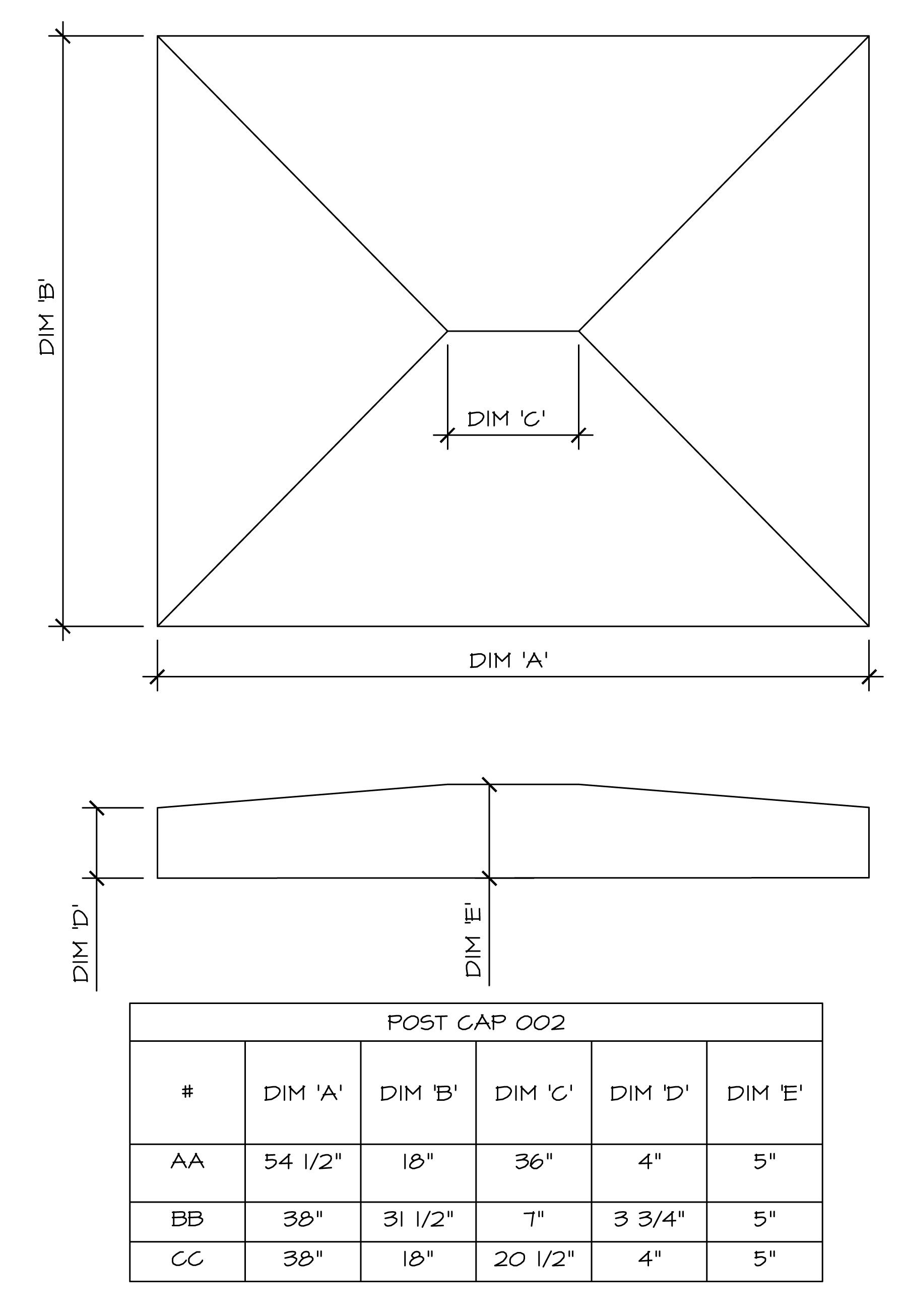

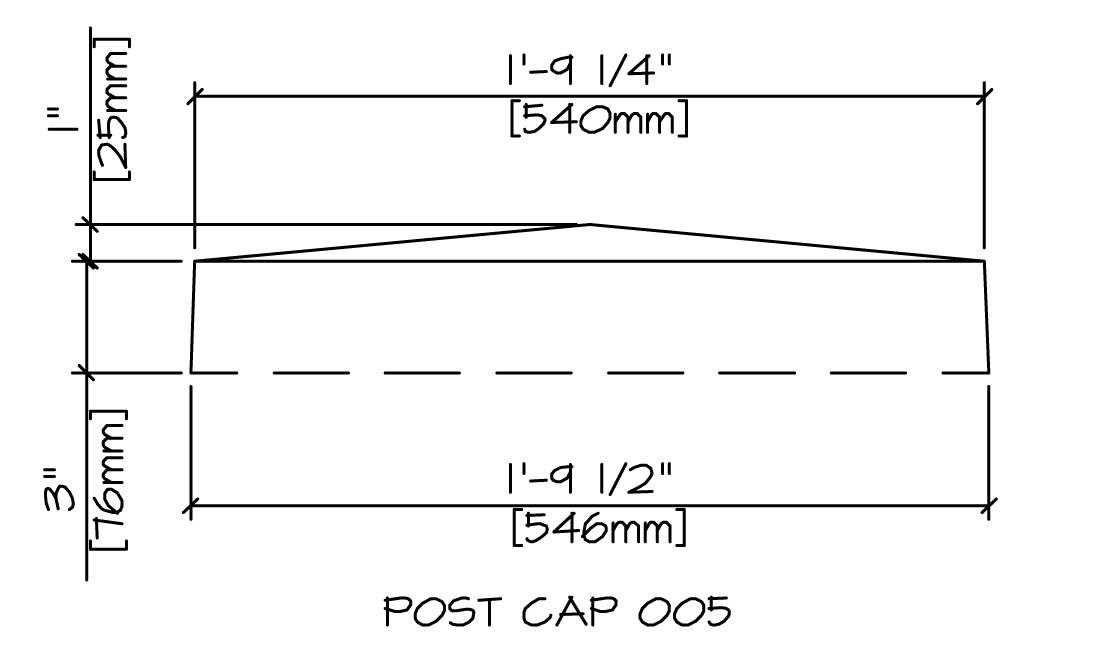

Scroll through the following pages to view shapes cast for past projects. Drawings for each shape are provided in .dxf and .dwg formats for easy import into project documents. If you dont see a shape that fits your next project, contact us for pricing.